A Sustainable Studio

The occasional twinkling of the bell followed by that loud and annoying industrial sound alerts us that the clay recovery and water-saving process is about to begin. While the booming machine sound may be disturbing and an unwelcome assault on our ears, it represents a very important process of creating a sustainable studio. For more than two years, the studio has been on a journey to establish systems and processes to conserve water and recycle clay.

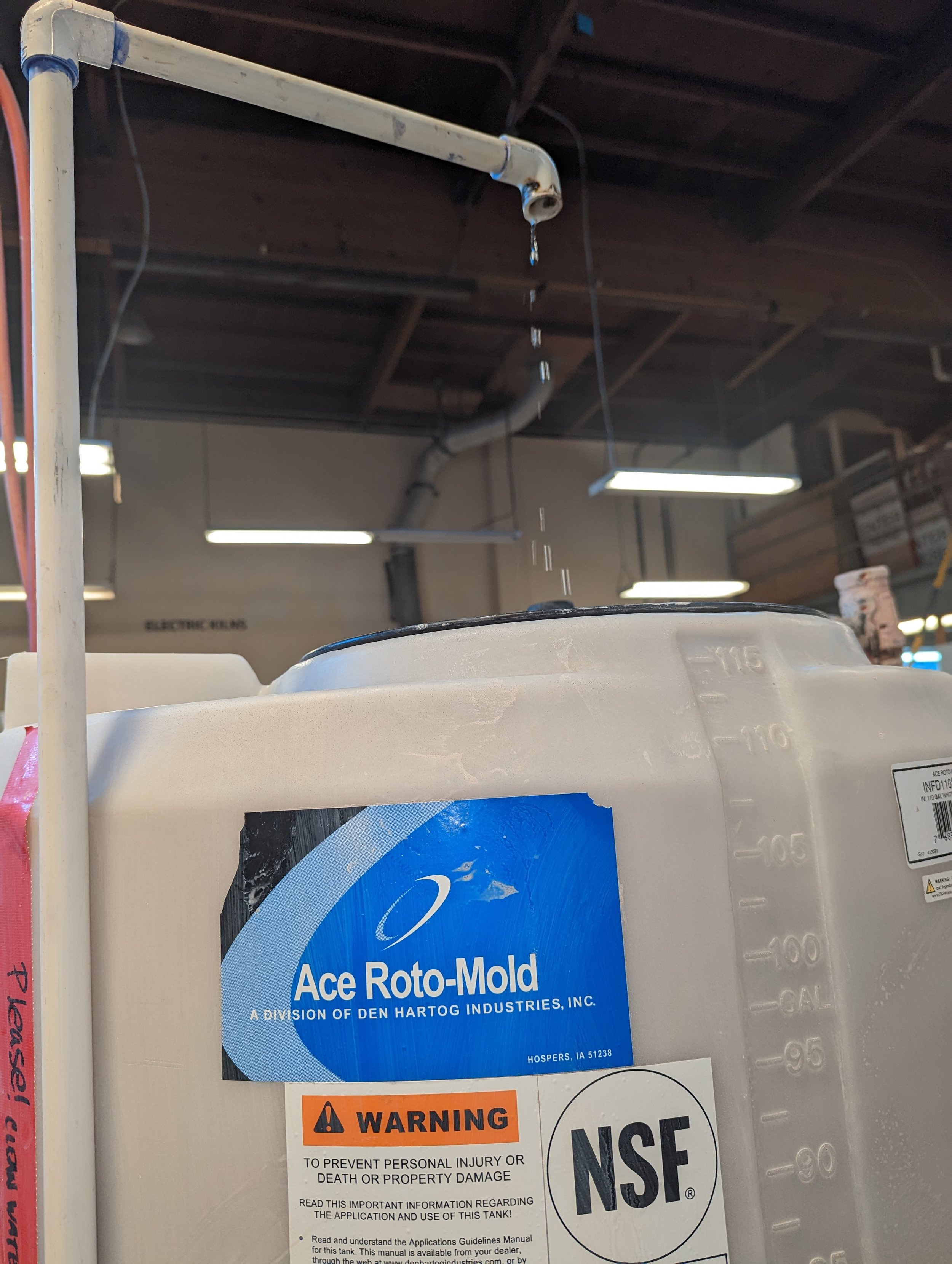

In 2019, the Board approved the purchase of the filter press located near the kiln yard. While it looks like something you might find in Willy Wonka’s Chocolate Factory it actually is an amazing filter system that saves thousands of gallons of water every six months and allows us to recycle 70 pounds of pugable clay every other day that is immediately available for use in the throwing classes and for resale. When the filter press (let’s call it the “Wonka”) arrived it came without any helpful instructions on how to put the Wonka together or how it worked. In fact, the Wonka only came with a single page of instructions and the manufacturer was less than helpful with information or assistance. Believe it or not, there were not even any YouTube “how to” videos available. When the studio closed down in 2020 due to Covid, staff took that opportunity to figure out how to put the Wonka together. Relying only on that one page of instructions and their own know-how and dogged determination, the Wonka was born. However, it was not until the summer of 2021 when people returned to the studio that the Wonka was finally placed into regular and constant service.

Many will remember those early days when without any warning at all the compressor would begin and the sound of the filter press attacked our delicate eardrums. Although brief, the sound was deafening. Little did we know that the noise was evidence of magic, sustainable magic. How many of us really understood what was going on or how frustrating the process was for staff? Did you ever see Sante scraping the clay out of the filters and wonder why? Did you even know that early on the Wonka broke down frequently, causing staff to question whether it was even worth all the trouble? Well, eventually Sante took this on as his pet project, his “raison d’etre”, and the automated process of recycling studio clay was born. Over the course of the past year, the process has been refined significantly. The first thing that occurred was the introduction of the lovely little twinkling bell warning that preceeds the compressors coming on. Next, the filtering schedule was adjusted so that the majority of the noise occurs overnight when the compressor runs.

So how does the magic happen? Unfortunately, the whole process involves more than a snap of the fingers or the tweaking of a hose. Although we call it magic, that is misleading because it is back-breaking and time-consuming work that the staff diligently performs every day. First, staff fills up the large containers with the barrels of clay and water from the sink area. This means they scoop out the contents of the large barrels of clay and water and sift before dumping into the Wonka rockets to extract the occasional tool left behind. Actually, not too occasional. Staff retrieves approximately 20 different tools from the barrels every week. Please, please, please check for tools before dumping your clay into the water. This definitely slows down the process and if a tool gets through this stage it can cause problems later down the road and possibly break the Wonka. Next, the pneumatic pump runs through the ten valves separating the water from the clay and then the compressor forces air against the material through the filters. The pumping occurs every other day at four different pressures and the compressor runs at night. Once this process is completed, staff removes the pugable clay in sheets from the filter and Rabi Parajapati (TPS staff member) runs the “platters” of clay through the pug mill and bags it up for resale.

Based on this process of collecting the clay and extracting the water, the Studio has been able to recycle both the water and the clay and prevent dumping large quantities of clay into the groundwater and into the trash, thus protecting the environment while engaging in sustainable practices.

The Studio also has a process for preventing glaze run-off from leeching into the groundwater. You have probably seen those bowls of “mush” right outside of the kiln yard. Those bowls are filled with contents from the rocket in the glaze area. Those bowls remain on those shelves until the water evaporates and then they are fired in those same bisque bowls and once they come out of the kiln they can be safely thrown away without harming the groundwater or the environment.

The Studio is currently working with an outside consultant to advance our sustainability including changing the studio over to LED lighting and changing our cleaning supplies to less impactful and harmful products. Although the Studio is not completely sustainable, these are just a few ways in which we are committed to protecting the environment through recycling clay and water, lighting and cleaning products. The process of recycling clay and water is a huge commitment by Staff to a process that makes a considerable difference. So the next time you hear the twinkling bell don’t groan or complain because it represents the magical process of recapturing grey water and recycling clay. Oh and don’t forget to check for your tools before dumping your wheel into the barrels.